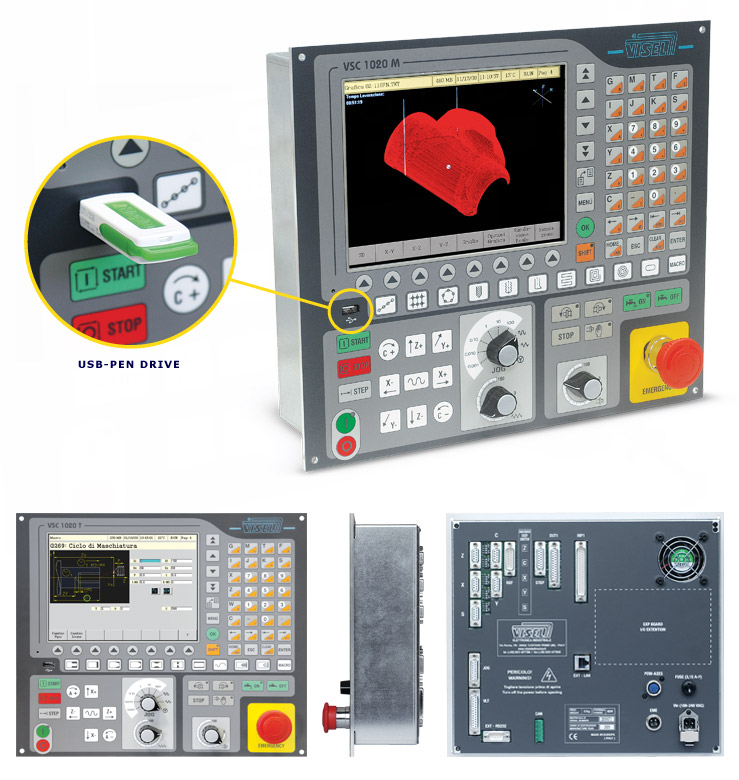

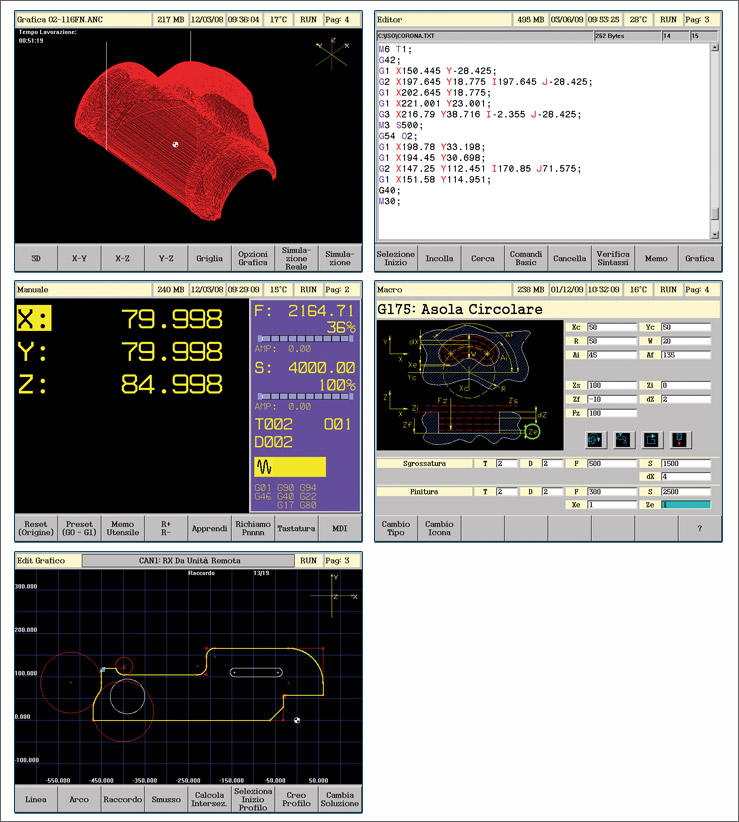

VSC 1020 – 1030 User Friendly CNC

Versatile, simple, practical and economical, the CNC series VSC1020 MT-1030 have been designed using extreme simplicity criteria for using with a

operator interface very practice and intuitable.

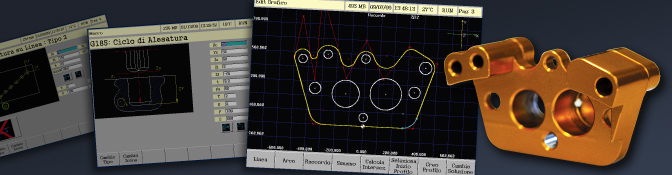

Highly complete, they allow to be programmed at various levels: ISO standard (G-code), by edit of defaults cycled (Macro), through the direct realization

of a graphic drawing on CNC (Edit VIS-CAM).

It’s possible to import files from external CAM through Ethernet network (LAN) or pen-drive (USB), for direct downloading in the internal memory

(standard) of 1 Gbyte flash.

|

FEATURES

- Same hardware configuration for both versions M- T

- Multi language select menù

- Possibility of programming during processing (MULTITHREADS)

- Hardware PC base embedded , dual processor, real-time

- 4 axis/ 5axis + spindle (control in position) management

- Linear, circular , helicoidal, interpolations

- Standard flash program memory 1 Gbyte

- UBS – Pen Drive interface

- ETERNETH interface connection

- CAN-BUS modules connection

- ISO – Parametric ISO standard programming

- Fixed cicles (Macro) conversational programming

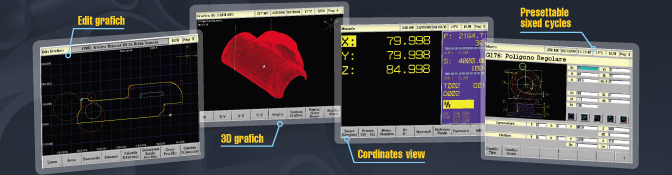

- Grafic Edit ( mini CAD-CAM included) with ISO profile converted

- Cicles (Macro) calling and execution direct from single key with icon or menù

- MACROMAKER PC program for build and import Macro to CNC by yourself (optional)

- Import and execution file from CAM

- Programs nesting management (40)

- Origins table (100 origins) managements

- MDI function with single block execution

- Advance 200 Tools table management (tools torque controls)

- 3D or single plane graphic view (with zoom function)

- Scale factor setting on each axes

- Roto-translation of view axis

- 3D dinamic graphic simulation (with tool show)

- Dinamic graphic simulation piece during the cicle (real – time)

- Graphic-percentual view of spindle torque

- Estimate total time piece execution + pieces counter function

- “TOOL INSPECTOR” function with tool repositioning and restart of the cycle from a point

- MECHATROLINK (Yaskawa) interface (optional)

- EtherCAT interface (optional)

- PLC management just included fo jog key, selector and override

- Allarm diagnostic data base

- Oscilloscope function for set up axis

- Logic Analizzator function for monitor In/Out states

|